Concrete is the backbone of modern construction. From foundations to bridges, skyscrapers to sidewalks, it is one of the most widely used building materials in the world. Yet, for all its versatility and strength, concrete is also one of the most weather-sensitive materials.

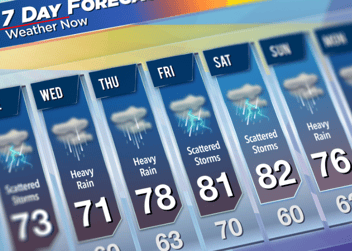

Planners and schedulers know the drill: when temperatures drop, hydration slows; when it’s too hot, water evaporates too quickly; when it rains, pours may be canceled entirely. Misjudging weather conditions for concrete work can lead to structural weakness, rework, or costly delays.

This makes concrete pouring one of the areas where weather downtime calendars are most critical. With accurate planning and modern tools, schedulers can move beyond rules of thumb to precise, data-backed approaches that enhance weather risk management and improve both weather resilience and climate resilience in their projects.

Why Concrete is So Sensitive to Weather

Concrete’s curing process depends on a delicate balance of temperature, humidity, and time. Deviations can cause long-term performance issues that may not show up until years later.

-

Cold weather: Below about 5°C (41°F), hydration slows dramatically. If the mix freezes before curing, the concrete can lose up to 50% of its strength.

-

Hot weather: High temperatures accelerate evaporation, causing shrinkage cracks, reduced strength, and durability problems.

-

Rain: Excess water during early curing can wash away cement paste, weaken surfaces, and delay setting.

-

Wind: Strong winds increase evaporation, leading to rapid surface drying and cracking.

For planners, this means that concrete pours cannot be scheduled without considering local weather conditions — both averages and extremes.

Traditional Approaches to Concrete Downtime

Historically, planners have used concrete downtime calendars or embedded rules within winter working calendars. For example:

-

“No pours in January.”

-

“Block 10 days of downtime per month in winter.”

-

“Add 2 extra days for curing buffers.”

While these assumptions create a safety net, they are imprecise. A project in Madrid may lose only 3 days in January, while one in Chicago may lose 15. Using the same assumptions for both wastes time and resources.

Moreover, these static rules rarely account for climate variability. Unseasonal heatwaves or cold snaps can cause unplanned delays that a simple downtime buffer won’t cover.

The Cost of Getting It Wrong

Poorly planned concrete pours can have significant financial and reputational costs:

-

Rework and Waste

If concrete doesn’t cure properly due to weather, it may need to be demolished and repoured — a waste of material, labor, and time. -

Structural Risk

Weak or compromised concrete can pose long-term safety risks, exposing contractors to liability and claims. -

Schedule Disruption

Concrete pours often sit on the critical path. A single delay can ripple through the entire project, affecting multiple trades and dependencies. -

Disputes and Claims

Without clear, data-backed weather calendars, contractors and clients often disagree on what counts as “reasonable” downtime.

Data-Driven Concrete Downtime Calendars

Today, contractors can replace blunt assumptions with data-driven calendars generated by a construction weather platform like WeatherWise. These calendars integrate:

-

Historical climate data — showing averages and extremes at the project’s exact location.

-

Activity-specific thresholds — e.g., blocking days where temperatures are forecast below curing thresholds or above critical evaporation points.

-

Probability windows — identifying days that may proceed with mitigation (e.g., curing blankets or accelerators).

-

Forecast overlays — updating calendars in real time as weather conditions evolve.

This approach moves concrete downtime planning from reactive to proactive — a key step in modern weather risk management.

Practical Steps for Planners

Here’s how schedulers can apply data-driven methods for concrete pours:

1. Identify Critical Temperature Ranges

Set clear thresholds for your project. For example:

-

Below 5°C → curing at risk.

-

Above 32°C → accelerated evaporation risk.

-

Wind above 20 mph → surface cracking risk.

2. Map Historical Weather Probabilities

Review how often these thresholds are breached during your planned construction period. For example, in Toronto, January might have a 70% probability of daily lows below 5°C, while Madrid might have only 10%.

3. Integrate into Scheduling Software

Import your downtime calendar into Primavera P6 or MS Project. This ensures downtime is embedded into the schedule logic rather than managed ad hoc.

4. Plan for Mitigation Measures

Mitigation can reduce downtime, but it has costs. Consider:

-

Heated enclosures or blankets in cold weather.

-

Retarders or accelerators in hot weather.

-

Adjusted work hours (e.g., early morning pours in summer).

5. Incorporate Climate Resilience

Factor in the likelihood of extremes, not just averages. With climate change, previously rare conditions (e.g., late spring freezes, early autumn heatwaves) are occurring more often. Building this into calendars enhances climate resilience.

Case Study: The Power of Precision

Two projects are scheduled to pour concrete in March:

-

Project A (Chicago): Uses a traditional winter calendar, assuming 10 downtime days. In reality, 14 days exceed cold weather thresholds. Crews scramble, pours are delayed, and claims arise.

-

Project B (Madrid): Uses a construction weather platform to generate a downtime calendar. Only 2 days are flagged as high risk. Pours proceed smoothly, with minor adjustments. The project finishes two weeks earlier than a competitor using a generic calendar.

The takeaway? Precision saves money, reduces risk, and boosts credibility with clients.

Building Weather Resilience in Concrete Work

Concrete pours will always be sensitive to weather, but data-driven planning transforms vulnerability into resilience. By using downtime calendars as part of a broader weather risk management strategy, contractors can:

-

Schedule pours with confidence.

-

Reduce disputes with data-backed evidence.

-

Optimize resource use by aligning labor and equipment with realistic windows.

-

Demonstrate weather resilience and climate resilience in tender documents, which increasingly matter to clients and insurers.

Final Thoughts

Concrete pouring is too critical — and too weather-sensitive — to be left to guesswork. Traditional downtime calendars are a step in the right direction, but they lack precision and adaptability.

By leveraging modern construction weather platforms, planners can create data-driven calendars that align schedules with reality. This shift doesn’t just save time and money; it enhances the resilience of projects in an era of growing climate uncertainty.