Winter Working Calendars: Do They Really Save Time and Money?

Every winter, construction planners across North America, the UK, and Europe brace themselves for the same challenge: weather downtime. Shorter daylight hours, freezing temperatures, snow, rain, and high winds all conspire to reduce productivity and increase the risk of costly delays.

To deal with this, many organizations use winter working calendars — pre-defined schedules that block out certain days or reduce productivity assumptions during the colder months. These calendars are meant to protect project timelines, provide a cushion for risk, and help keep budgets realistic.

But here’s the big question: are winter working calendars really effective at saving time and money? Or are they blunt instruments that often lead to inefficiency, overestimations, and missed opportunities?

The Origins of Winter Working Calendars

Winter working calendars emerged as a pragmatic solution in an era before advanced climate data was easily available. Contractors and engineers knew that winter posed risks, so they developed simplified rules of thumb, such as:

-

Assume 5–10 non-working days per month in December through February.

-

Reduce labor productivity by 30–40% during the coldest periods.

-

Prohibit specific activities (e.g., concrete pours, roofing, paving) below certain temperatures.

The intent was sound: plan conservatively to avoid surprises. For decades, these calendars were the industry standard.

The Benefits of Winter Working Calendars

Despite their shortcomings, winter working calendars do provide value:

-

Simplicity

They give planners a clear, easy-to-apply framework for adjusting schedules. Even small contractors without access to sophisticated data can implement them. -

Risk Buffer

By assuming downtime in advance, they reduce the likelihood of catastrophic delays caused by unplanned winter conditions. -

Stakeholder Clarity

Clients, insurers, and regulators often expect to see winter downtime reflected in schedules. Winter working calendars meet this expectation.

For many organizations, they remain a useful “good enough” tool, particularly for short projects or those with limited exposure to severe winter conditions.

The Limitations and Hidden Costs

However, winter working calendars also come with drawbacks — ones that are becoming more significant as projects grow in complexity and as weather patterns shift.

1. Overestimation of Downtime

By assuming a fixed number of lost days, winter working calendars often overstate the true impact of weather. For example:

-

A project in southern England may build in 15 downtime days for January, yet only lose 5 in reality.

-

In warmer US states, winter calendars may assume freezes that rarely occur.

This inflates project schedules, tying up capital, resources, and labor longer than necessary.

2. Underestimation in Harsh Climates

Conversely, in colder or more variable climates, a standard winter calendar may underestimate downtime. A project in Montreal could easily face more lost days than a generic calendar predicts, leading to disruptions and disputes.

3. Ignoring Activity-Specific Risks

Winter working calendars are typically blunt. They don’t distinguish between activities. Yet concrete pouring, steel erection, and excavation have very different sensitivities to weather.

4. Lack of Climate Resilience

Perhaps most importantly, traditional calendars rely on historical norms that may no longer apply. Climate change is altering weather patterns: extreme cold snaps, rain-on-snow events, and erratic temperature swings are more common. A static winter working calendar does not account for these shifts — reducing climate resilience in planning.

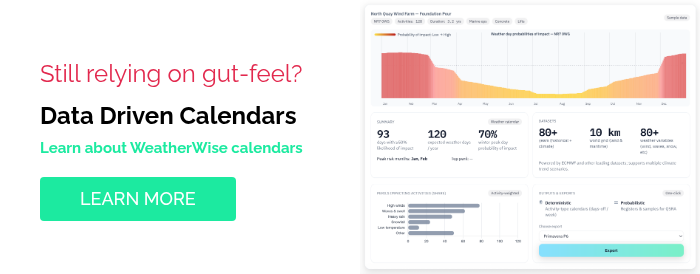

Data-Driven Alternatives

This is where modern tools like construction weather platforms step in. Rather than relying on fixed, static winter calendars, planners can now generate data-driven weather downtime calendars.

These offer:

-

Regional precision — tailored to the specific project location, not just a broad climate zone.

-

Probability-based downtime — showing the likelihood of disruption on each day or week.

-

Activity-specific filters — downtime tailored to the sensitivities of concrete, roofing, paving, etc.

-

Integration with scheduling software — outputs that drop directly into Primavera P6, MS Project, or BIM tools.

This approach transforms winter downtime from a vague assumption into a quantifiable element of weather risk management.

A Real-World Example

Consider two projects starting in November:

-

Project A (London, UK) uses a traditional winter working calendar, blocking 10 days of downtime for each winter month. In reality, December experiences only 3 major weather disruption days. The project ends up padded with 21 “unnecessary” downtime days, inflating the budget and tying up resources.

-

Project B (Boston, USA) uses a construction weather platform to build a data-driven calendar. The model predicts an average of 14 downtime days in January due to freezing temperatures, compared to the 10 assumed in a generic winter calendar. By planning accordingly, the project avoids major rescheduling headaches.

The difference? Project B saves money by avoiding disputes and delay claims, while Project A loses money by over-allocating downtime.

Toward Smarter Winter Planning

Winter working calendars will likely continue to play a role, especially for smaller contractors or projects with limited resources. However, their limitations are clear. In an era where data is more accessible than ever, relying solely on static calendars is increasingly a missed opportunity.

Forward-looking planners are moving toward:

-

Integrated downtime calendars that reflect local climate realities.

-

Weather resilience strategies that consider not just averages, but extremes.

-

Dynamic updates that adjust calendars as forecasts shift.

-

Holistic weather risk management, where downtime is considered alongside safety, cost, and resource planning.

This shift not only saves time and money — it also helps contractors demonstrate leadership in climate resilience, which is becoming a differentiator in tenders, financing, and insurance.

Final Thoughts

So, do winter working calendars really save time and money? The answer is: sometimes. They provide a useful baseline, but they are no substitute for precision. In fact, their over-simplicity often costs projects more than it saves.

The future lies in data-driven downtime calendars that turn weather from an unpredictable wildcard into a manageable, quantifiable risk. By adopting these tools, contractors can reduce inefficiencies, cut costs, and build greater resilience into their projects.

In short: winter working calendars were a good solution for the past. Data-driven weather calendars are the solution for the future.