You need a cold weather concrete plan because the lowest temperature to pour concrete or minimum temperature to pour concrete is not as low as you think, making it a key construction risk.

Concrete, the fabric of our society

Concrete is one of, if not the most, ubiquitous building materials on our planet. It is used across the industry in use case after use case. It’s highly flexible and malleable. It can be poured on site, pre-cast and brought on trucks, or even 3D printed. This versatility, combined with its high specs and cheap cost has made it a staple on projects large and small.

However, concrete is not a wonder material with no downsides. Whilst it is an incredibly useful material, it also happens to be responsible for 4-8% of global greenhouse gas emissions. That is more than all cars and planes combined. But that’s not what this piece is about. We’ll save that for another time. For now, concrete is not going anywhere.

Concrete process

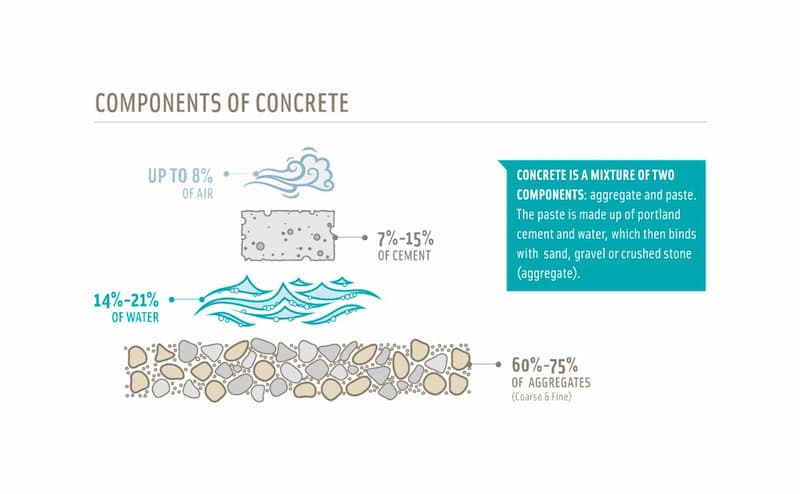

Today, we want to discuss the risks associated with deploying concrete on your building site or project. Concrete is made up of small rock fragments (usually clinker) combined with cement and water. As these materials are mixed a process known as hydration occurs. This chemical reaction solidifies the cement paste and binds it all together to create an extremely hard solid.

Image from cement.org

Image from cement.org

This mixture will tend to dry or harden within 48 hours. The process for this surface to fully set, or cure will go on for up to 28 days. At this point the concrete will have reached its maximum strength. If the mixture is disturbed during this time it can result in a weakened end product.

What happens in the cold?

The process of hydration that gives concrete its strength is initially very sensitive to the cold. Especially in the first 24 hours, if the water in the concrete mixture starts to get ice crystals within it, then the mixture could lose up to 50% of its designed strength.

It is also important not to pour on top of a cold or frozen surface either. Waiting until the ground temperature is 5℃ and rising will give you the best chance of avoiding any negative consequences.

If you are pouring in winter then laying thermal blankets, providing wind shelters and other protective measures is essential as this will minimise any risk that the product will suffer tensile strength issues.

Concrete rework, the cost

Even if you have taken all these measures, cold weather can still result in a reduction in strength. If this happens then in the worst-case scenario the concrete will need to be removed and repoured. Rework in construction is a not insignificant cost, with estimates landing it at around 4-6% of total project costs. If you do have to take concrete out because of cold weather, then you first need to chip away the partially hardened concrete and prepare the surface to have another pour.

Having to do this type of rework is incredibly disheartening and so that's why keeping an eye out for low temperatures and trying to avoid pours at times when the lowest temperatures to pour concrete are likely to occur is a good idea that will save time and money in the long run.

How to avoid pouring at the wrong time?

The minimum temperature to pour concrete is technically 0℃ however at this temperature there is a high chance of damage. Most operators will look for 5℃ and rising for the time when they will start their pour. Even this requires a watchful eye as the ground will be colder than the air temperature and pouring onto frozen ground as we have already seen is a very bad idea.

Getting critical temperature warnings and alerts will help site operators decide whether to go ahead with that pour. Warnings that are relevant to the activities you have planned that week can help you understand which day is likely to offer the best temperature windows to get the pour done.

Once that pour is done then putting down blankets and making sure the temperature of the mixture doesn’t drop below 4℃ for the next few days will provide certainty that the concrete can reach the correct tensile strength. If you have accurate weather data aligned with the planned activities you will be more easily able to understand your optimal weather window.

Is climate change an opportunity?

In most areas across the world temperatures are rising. Some are rising much more quickly than others! For example the arctic has seen considerably more warming in the last decade than the global average, read more about this here. What this means for those wanting to know about when to pour concrete is that there could be hidden opportunities lying in wait.

Before diving into this opportunity though it should be caveated with this; concrete is a leading cause of climate change, because clinker, one of the main components in the mixture, is incredibly energy intensive to create. The carbon emissions of Co2 as a whole are second only to emissions produced by China and the USA. These emissions need to be falling by 3% annually to meet our 2030 NetZero targets, and we are not at all on track with this as it stands today in 2022.

The industry has made pledges, there are new types of concrete and materials being deployed and scaled, but not fast enough to meet our targets.

If you do happen to be pouring concrete however then getting accurate information about local climate trends will help you understand if there are new times when pouring might now become more feasible.

For example, many contractors have calendars that block out winter for concrete pours, but now that winter is becoming a warmer season there may well be ways to accelerate your concrete pouring programme. If you leverage data then you can become more competitive, save time and ultimately generate greater profits.

A smart approach to your concrete cold weather plan

So, if you are conscious of the lowest temperatures to pour concrete you will want good data to help inform you. If you have a cold weather plan in place that helps you leverage this data and make use of blankets, windbreaks and other physical items then low temperatures will do less to slow down your progress than you might think.

If you want to know more about how the EHAB enhanced planner can help you with your concrete pours and identifying the best weather windows, then all you need to do is reach out here. We’re more than happy to share data and insights into the local climate trends at your project location to help you understand if there is an opportunity for an accelerated pouring schedule.